Standard spline shaft dimensions ensure precise mechanical connections‚ enabling efficient torque transmission in automotive‚ aerospace‚ and industrial applications. DIN‚ SAE‚ and JIS standards provide uniform specifications for spline profiles‚ diameters‚ and tooth counts‚ crucial for interoperability and reliability in machinery design. Understanding these dimensions is essential for selecting the right components‚ optimizing performance‚ and maintaining safety across various industries.

Definition and Overview of Spline Shafts

A spline shaft is a mechanical component featuring a series of teeth or ridges along its length‚ designed to mate with corresponding grooves in a hub or gear‚ enabling torque transmission. Unlike keyed shafts‚ splines provide a more precise and secure connection‚ allowing for higher torque capacity and resistance to rotational stress. Involute splines‚ defined by their curved tooth profile‚ are common due to their strength and resistance to wear. Standardized by specifications like DIN‚ SAE‚ and JIS‚ spline shafts ensure compatibility and interchangeability across different systems. Their design involves critical parameters such as pitch diameter‚ number of teeth‚ and material selection‚ all detailed in technical PDF documents for precise engineering applications.

Importance of Standard Spline Shaft Dimensions

Standard spline shaft dimensions are critical for ensuring compatibility‚ reliability‚ and optimal performance in mechanical systems. These standards‚ outlined in PDF documents‚ provide uniform specifications for spline profiles‚ tooth counts‚ and diameters‚ reducing design variability and potential failures. By adhering to established standards like DIN‚ SAE‚ and JIS‚ engineers achieve precise alignment and torque transmission‚ minimizing wear and tear. Standardization also simplifies manufacturing processes‚ ensuring consistency across production lines and enabling the interchange of components from different suppliers. This uniformity is vital in industries like automotive and aerospace‚ where system integrity and safety depend on accurate and reliable connections‚ making standard spline shaft dimensions indispensable for efficient and durable mechanical designs.

Common Applications of Spline Shafts

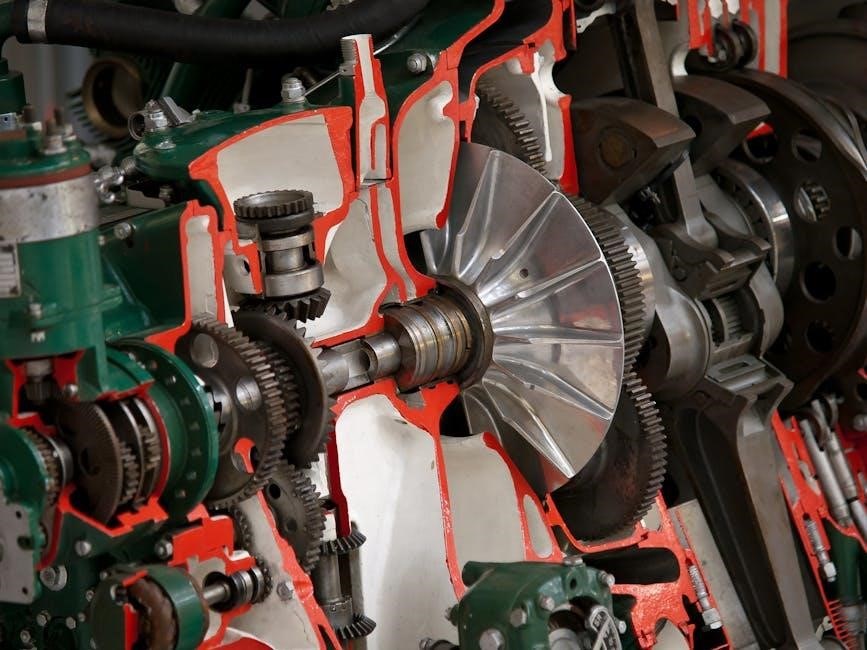

Spline shafts are widely used in various industries due to their ability to transmit torque and rotational motion efficiently. In the automotive sector‚ they are integral to gearboxes‚ driveshafts‚ and steering systems. Aerospace applications include engine components and landing gear mechanisms‚ where high precision and durability are crucial. Industrial machinery relies on spline shafts for power transmission in pumps‚ motors‚ and gearboxes. Additionally‚ they are used in robotics and CNC machinery for precise motion control. Their versatility and strength make them a key component in systems requiring reliable torque transfer‚ ensuring smooth operation across diverse mechanical systems. The use of standardized spline shaft dimensions‚ as detailed in PDF specifications‚ further enhances their applicability and compatibility in these industries.

Understanding Spline Shaft Standards

Spline shaft standards like DIN‚ SAE‚ and JIS specify tooth profiles‚ diameters‚ and tolerances‚ ensuring mechanical interoperability and manufacturing consistency across various industries and applications globally.

DIN Spline Standards (DIN 5480 and DIN 5482)

DIN 5480 and DIN 5482 define specifications for involute spline connections‚ focusing on nominal dimensions‚ tolerances‚ and inspection methods. These standards ensure compatibility and precision in mechanical components‚ particularly for high-performance applications; DIN 5480 covers the fundamental principles‚ while DIN 5482 provides detailed inspection criteria. Together‚ they facilitate the design and manufacture of spline shafts with uniformity and reliability‚ adhering to European industrial practices.

SAE Spline Standards

SAE (Society of Automotive Engineers) spline standards provide detailed specifications for spline shafts‚ ensuring compatibility and performance in automotive and industrial applications. These standards define nominal diameters‚ tooth counts‚ and pitch diameters‚ with codes like AA (9T‚ 20/40 DP) offering specific configurations. SAE standards cover both straight and involute splines‚ with a focus on precise tolerances and material requirements. They are widely used in high-performance scenarios‚ ensuring reliable torque transmission and dimensional accuracy. By adhering to SAE standards‚ manufacturers can select and produce spline shafts that meet strict engineering demands‚ facilitating efficient design and assembly across various industries.

JIS Spline Standards

JIS (Japanese Industrial Standard) spline standards‚ such as D 2001:1959‚ specify dimensions for straight‚ non-helical‚ 20-degree pressure angle‚ stub tooth‚ involute splines. These standards provide nominal diameters‚ tooth counts‚ and modules‚ as seen in examples like 35T12x2.5‚ where 35 is the nominal diameter‚ 12 the number of teeth‚ and 2.5 the module. Materials like C45 steel‚ stainless steel‚ and bronze are commonly used. JIS standards ensure uniformity in spline shaft design‚ aiding manufacturers in selecting components for precise torque transmission. By adhering to these standards‚ industries in Japan and globally achieve reliability and consistency in mechanical systems‚ facilitating efficient design and assembly across various applications.

Spline Shaft Design and Dimensions

Spline shaft design involves precise dimensions like major and minor diameters‚ pitch‚ and tooth profiles. Material selection and heat treatment ensure durability and optimal performance in machinery.

Key Dimensions of Spline Shafts

The key dimensions of spline shafts include the major diameter‚ minor diameter‚ pitch diameter‚ and tooth thickness. These measurements ensure proper fitment and torque transmission. The major diameter is the outermost dimension of the spline teeth‚ while the minor diameter is the innermost‚ defining the spline’s root. The pitch diameter‚ calculated from the circle passing through the teeth tips‚ is critical for determining the pitch and tooth count. Form diameter‚ which includes the tooth depth‚ ensures the spline’s structural integrity. These dimensions are standardized in specifications like DIN 5480 and SAE J526 to guarantee compatibility across applications. Accurate measurement and adherence to tolerances are essential for reliable performance in machinery. Proper alignment and surface finish further enhance the spline shaft’s efficiency and longevity.

Material Selection for Spline Shafts

Material selection for spline shafts is critical to ensure durability‚ strength‚ and resistance to wear. Common materials include high-strength steels like AISI 1045 and C45‚ which offer excellent mechanical properties for torque transmission. Stainless steel‚ such as 1.4305‚ is chosen for corrosion resistance in harsh environments. Bronze alloys‚ like GC-CuSnZnPb‚ are used for their high wear resistance and ability to operate under heavy loads without lubrication. The choice of material depends on the application‚ load conditions‚ and required lifespan. Heat treatment‚ such as induction hardening‚ is often applied to enhance surface hardness and fatigue resistance. Standards like DIN and SAE provide guidelines for material selection‚ ensuring compatibility and performance across various industries. Proper material selection ensures the spline shaft meets design requirements and operates reliably under stress.

Heat Treatment and Surface Finishing

Heat treatment and surface finishing are critical processes for spline shafts to enhance their mechanical properties and durability. Induction hardening is commonly applied to increase surface hardness and improve resistance to wear and fatigue‚ especially in high-stress applications. Case hardening is another method used to strengthen the outer layers while maintaining a tough core. Surface finishing techniques‚ such as grinding and shot peening‚ are employed to achieve precise dimensional tolerances and reduce stress concentrations. Electroplating or coatings may be applied for corrosion resistance. These processes ensure the spline shaft meets stringent performance requirements and extends its operational lifespan. Standards like DIN and SAE provide guidelines for heat treatment and finishing‚ ensuring consistency and reliability in industrial and automotive applications.

Manufacturing Considerations

Spline shaft manufacturing involves precise processes like hobbing‚ grinding‚ and broaching to achieve exact dimensions. Heat treatment‚ such as induction hardening‚ enhances durability. Quality control ensures accuracy and surface finish.

Processes Involved in Spline Shaft Production

The production of spline shafts involves several precise manufacturing processes. Initially‚ the shaft is turned to the required diameter using CNC lathes. Hobbing is then employed to cut the spline teeth‚ ensuring the correct pitch and profile. For internal splines‚ broaching is often used to create the desired tooth form. Grinding may follow to achieve tight tolerances and a smooth surface finish. Heat treatment‚ such as induction hardening‚ is applied to enhance the shaft’s durability and wear resistance. Finally‚ quality control measures‚ including dimensional inspections with calliper gauges and tooth thickness checks‚ ensure compliance with standards like DIN 5480 and DIN 5482. Each step is critical to producing a spline shaft that meets the specified dimensions and performance requirements.

Quality Control and Tolerances

Quality control is integral to ensuring spline shafts meet specified standards. Tolerances are critical‚ with parameters defined for pitch‚ tooth thickness‚ and major and minor diameters. Inspection typically involves gauges‚ such as GO and NO-GO gauges‚ to verify dimensions. Surface finish and concentricity are also evaluated to prevent operational issues. Manufacturers adhere to standards like DIN 5480‚ which outlines permissible deviations. Proper documentation and traceability are maintained to ensure compliance. Advanced metrology tools‚ such as coordinate measuring machines‚ may be used for precise measurements. These practices ensure reliability and interchangeability in spline shaft applications across industries‚ maintaining performance and safety standards.

Geometric Tolerances for Spline Shafts

Geometric tolerances for spline shafts are critical to ensure precise alignment and functionality. These tolerances define acceptable deviations in features like pitch‚ tooth profile‚ and major/minor diameters. Standards such as DIN 5480 and SAE specifications outline these limits‚ ensuring uniformity. Inspections often use specialized gauges‚ including spline plug gauges‚ to verify compliance. Surface finish and concentricity are also monitored to prevent vibration and wear. Deviations exceeding tolerance limits can lead to operational issues‚ making adherence crucial. By maintaining these standards‚ manufacturers ensure spline shafts are reliable and interchangeable across applications‚ contributing to overall system performance and longevity.

Applications of Spline Shafts

Spline shafts are widely used in automotive‚ aerospace‚ and industrial machinery for precise torque transmission. Their reliability and durability make them ideal for high-performance applications.

Automotive Industry Applications

In the automotive industry‚ spline shafts are integral to power transmission systems‚ ensuring smooth torque transfer. They are commonly used in drive shafts‚ gearboxes‚ and steering systems. SAE standard spline shafts are widely adopted for their precision and reliability. These shafts are designed to withstand high rotational forces and misalignment‚ making them ideal for vehicle applications. Automotive manufacturers rely on standardized spline dimensions to maintain compatibility and performance across components. From manual to automatic transmissions‚ spline shafts play a critical role in ensuring efficient power delivery. Their durability and resistance to wear also contribute to the overall longevity of automotive systems‚ making them a cornerstone of modern vehicle design.

Aerospace Industry Applications

In aerospace engineering‚ spline shafts are employed in critical systems requiring precise torque transmission and reliability. They are used in aircraft engines‚ gearboxes‚ and actuation mechanisms. SAE and DIN standards are commonly referenced for their high-precision dimensions‚ ensuring minimal wear and maximum efficiency. Aerospace applications demand stringent tolerances and durability due to extreme operating conditions. Spline shafts in this sector are designed to handle high rotational speeds and stresses while maintaining dimensional accuracy. Their use extends to helicopter rotors and landing gear systems‚ where failure is not an option. The aerospace industry’s reliance on standardized spline dimensions underscores their importance in achieving operational excellence and safety in flight-critical components.

Industrial Machinery Applications

Industrial machinery relies heavily on spline shafts for power transmission in demanding environments. They are integral to gearboxes‚ pumps‚ and conveyors‚ ensuring efficient torque transfer. Standardized dimensions‚ particularly from DIN and ISO specifications‚ are crucial for compatibility and reliability. In manufacturing‚ spline shafts are used in robotics‚ hydraulic systems‚ and heavy-duty equipment‚ where precision and durability are essential. Their ability to handle high loads and minimize wear makes them ideal for continuous operation. Additionally‚ spline shafts in industrial machinery are often heat-treated and finished to enhance performance under harsh conditions. The use of standardized spline dimensions ensures seamless integration and maintenance across various industrial applications‚ contributing to overall operational efficiency and cost-effectiveness.

Reading and Interpreting Spline Shaft PDF Documents

Understanding technical specifications in PDFs is crucial for precise spline shaft dimensioning. These documents detail nominal dimensions‚ tolerances‚ and inspection methods‚ ensuring accurate mechanical design and compliance with standards like DIN and SAE.

Understanding Technical Specifications in PDFs

Technical specifications in PDFs provide detailed information on spline shaft dimensions‚ including nominal diameters‚ tooth counts‚ and pitch values. These documents outline material requirements‚ heat treatment processes‚ and surface finishing standards. They also specify geometric tolerances‚ ensuring precise manufacturing. Compliance with standards like DIN 5480 and SAE is emphasized‚ covering key parameters such as major and minor diameters. Symbols and terminology are standardized‚ facilitating clear communication among engineers. Proper interpretation of these PDFs is essential for designing and manufacturing spline shafts that meet performance and safety requirements across various industries.

How to Use Spline Shaft Dimension Tables

To effectively use spline shaft dimension tables‚ start by identifying the spline type (e.g.‚ involute or straight) and its standard (e.g.‚ DIN‚ SAE‚ or JIS). Locate the relevant table in the PDF document‚ focusing on key dimensions such as major and minor diameters‚ pitch‚ and number of teeth. Match these dimensions to your application requirements‚ ensuring compatibility with mating components. Pay attention to tolerances and surface finish specifications to maintain precision. Cross-reference with material and heat treatment guidelines to ensure optimal performance. Proper interpretation of these tables ensures accurate design and manufacturing‚ minimizing errors and enhancing mechanical efficiency in your project.

Common Symbols and Terminology in Spline Shaft PDFs

Spline shaft PDFs utilize specific symbols and terms to convey technical specifications. Common terms include major diameter (D)‚ minor diameter (d)‚ and pitch diameter (Dp)‚ which define the spline’s geometric profile. The number of teeth (Z) and module (m) specify tooth size and spacing. Symbols like tolerance classes (e.g.‚ IT7‚ IT8) indicate manufacturing precision‚ while surface finish (e.g.‚ Ra) ensures compatibility. Terms such as involute describe tooth geometry‚ and heat treatment specifies material properties. Understanding these symbols and terms is crucial for accurate interpretation of spline shaft dimensions and ensuring proper component integration in mechanical systems.

Standard spline shaft dimensions are critical for ensuring mechanical compatibility and performance; Referencing DIN‚ SAE‚ and JIS standards‚ along with official PDF documents‚ provides detailed specifications for design and manufacturing. Always consult these resources for precise spline shaft applications.

Standard spline shaft dimensions are essential for ensuring compatibility‚ efficiency‚ and reliability in mechanical systems. Key standards like DIN 5480‚ DIN 5482‚ SAE‚ and JIS provide detailed specifications for spline profiles‚ diameters‚ and tooth counts. These standards enable precise design and manufacturing‚ minimizing errors and enhancing performance. PDF documents serve as critical resources‚ offering tables‚ diagrams‚ and technical specifications for splined connections. Proper material selection‚ heat treatment‚ and surface finishing further optimize spline shaft functionality. Adhering to these standards ensures seamless integration across automotive‚ aerospace‚ and industrial applications. Always consult relevant PDFs and technical guides for accurate implementation and compliance with international norms.

Recommended Resources for Further Reading

For comprehensive understanding‚ refer to DIN 5480 and DIN 5482 standards for detailed spline specifications. SAE and JIS documents provide additional insights into regional requirements. Technical gear guides and manufacturer catalogs‚ such as those from Misumi or McMaster-Carr‚ offer practical design data. Academic publications on mechanical engineering‚ like “Design of Machinery” by Norton‚ include in-depth analyses. PDF resources from industrial associations and engineering toolkits like CUBIT are invaluable for precise calculations. Consulting these resources ensures adherence to global standards and optimizes spline shaft applications across industries.